Combustion Analysis: Why It's So important

Today we would like to talk about why combustion analysis is so important and why you should have it done.

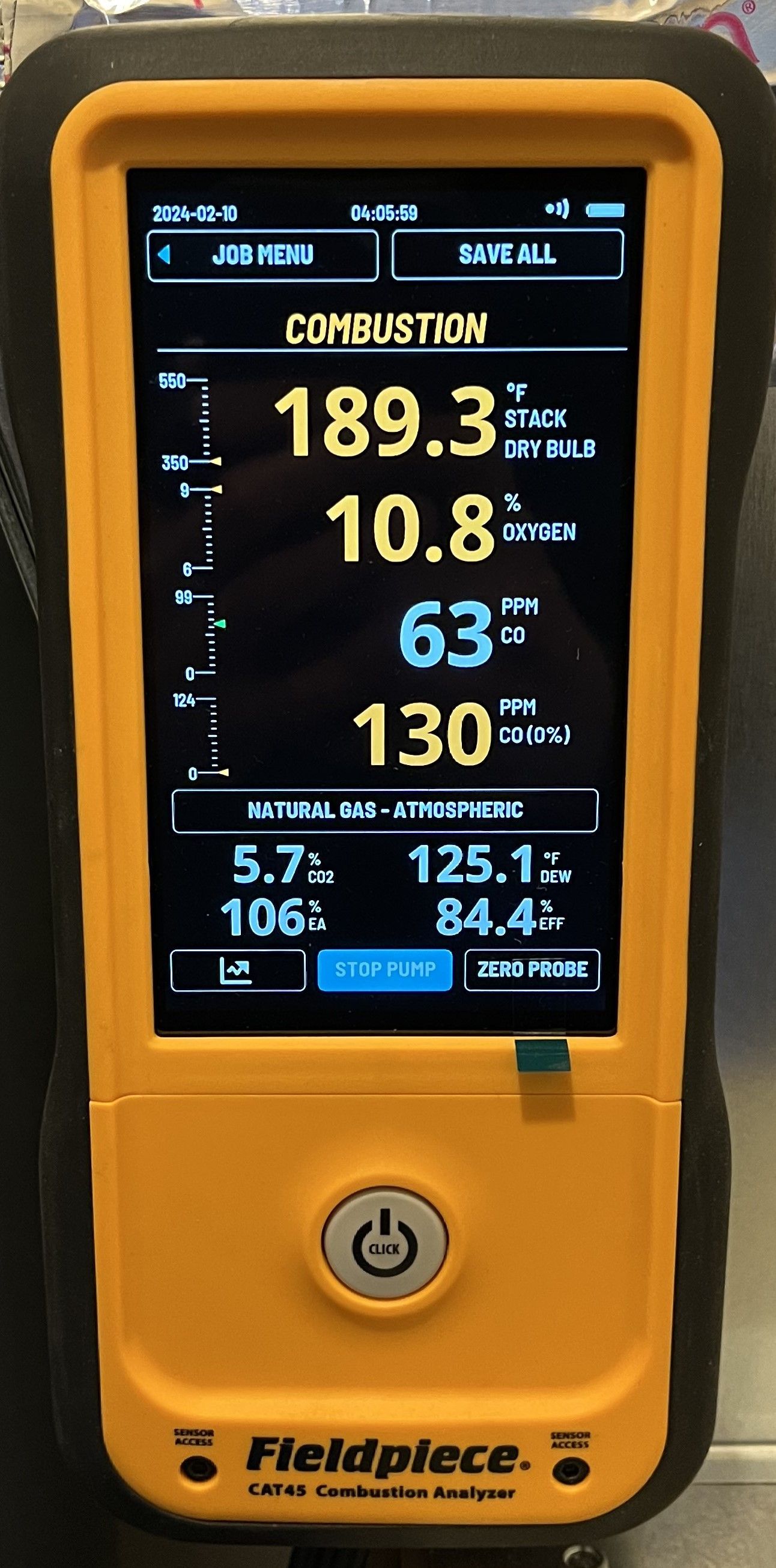

Efficiency

Your furnace comes rated from the factory at a certain efficiency, but did you know that is just a speculative

rating and not the true efficiency the furnace is running at? The only way to truly measure efficiency and

get the most out of your furnace is to test the exhaust product in the flu pipe and tune the gas pressures.

Most furnaces come rated from the manufacturer with basic efficiency numbers like 80%, 92%, 96%, etc.

With out combustion analysis and tuning those numbers are most likely lower. It is possible to squeeze

higher efficiency numbers out of your furnace when properly tuned. Ultimately, saving you real money on

your gas bills.

Extending your furnace’s lifespan

In the United States, warranty claims on new equipment are over 30%. In Europe warranty claims on new

equipment are less than 5%. The reason? European laws require a combustion analysis be performed

when commissioning any new piece of gas fired heating equipment. Having properly tuned combustion

means soot and harmful chemicals that cause furnaces to prematurely fail are eliminated leading to a

reduced failure rate and maximum life expectancy.

Safety and the “Cracked Heat Exchanger”

On top of getting the highest efficiency your furnace is capable of, combustion analysis can tell us if your

furnace is safe to operate. Many of us have heard the dreaded words “You have a cracked heat

exchanger”. Whether it was your own experience or a friend or neighbor telling you about theirs. When a

technician tells you this, followed by saying you need to buy a new furnace, always make sure you request

some sort of proof you can see to support their claim.

The best way to be absolutely 100% sure you are being told the truth is by combustion analysis. Analyzing

the exhaust product can tell us if fresh oxygen is being added to the exhaust through a hole or crack in the

heat exchanger. This is by far the best way to have concrete proof the heat exchanger is indeed cracked.

Of course, some cracks when large enough can be seen visually with an inspection camera as well.

If the technician isn’t providing you with proof of the cracked heat exchanger by either taking you to the

furnace and showing you the crack visually with an inspection camera or by showing you a combustion

analysis, be skeptical and get a second opinion.

02-18-2024

Erik Koster Owner ThermPro Heating & Cooling